METALLURGICAL TESTING

PMMT Testing Lab

We have a well-equipped Lab in which we carry out periodic testing of samples and coupons using same parameters and raw material which will be used for actual jobs. This regular exercise keeps a check on our quality. With this we confirm that we are providing the repeatability as per the customers’ set process qualifications. Our lab is having facility to cut samples, mould them into test coupons and polish it for testing.

Some of the Tests Carried out in the Lab are:

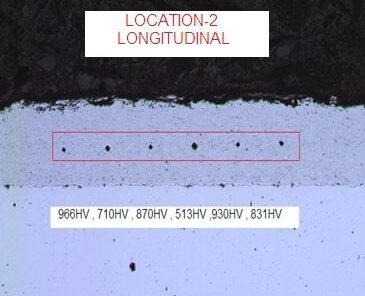

- Micro Hardness Testing

- Microstructure Testing with Microscope.

- Abrasion / Wear Testing.

- Measuring instruments like FARO arms, Bore gauges, Micrometers, Verniers etc.

Microstructure Testing:

Pictures showing some of the tests done in our lab:

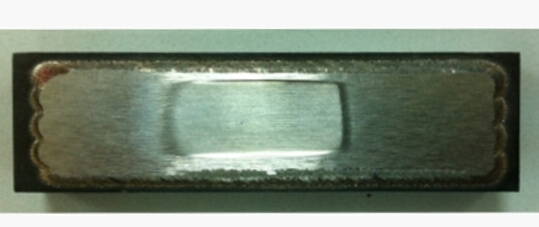

Moulds for Testing

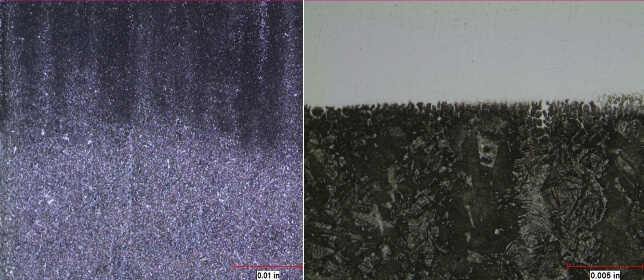

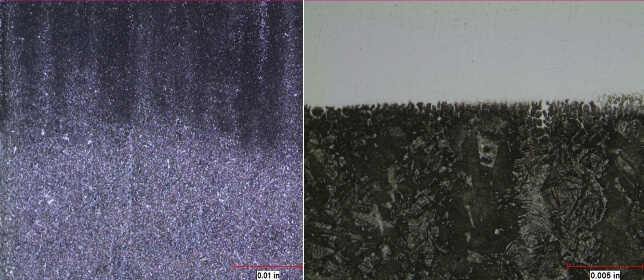

Microstructure Testing (Bonding in cladding area)

Microstructure Testing (Hardening area)

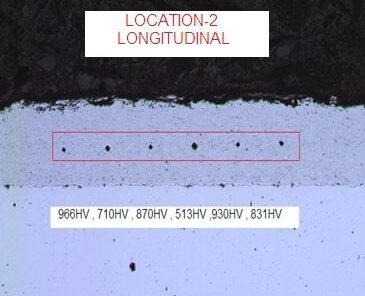

HVOF Microstructures showing diamond indentation for hardness and bonding between base material and overlay. Porosities and Oxide formation testing also done.

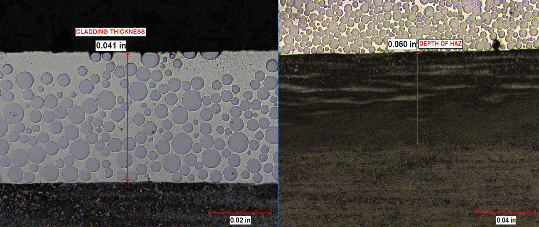

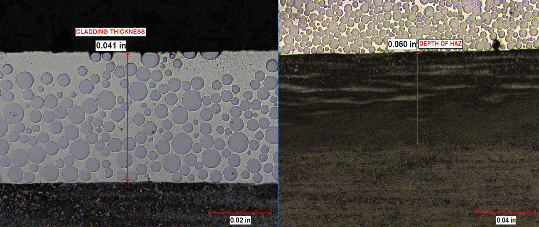

Cladding Microstructures showing bonding, cladding thickness and HAZ.

Wear Testing:

- As per ASTM G65 Dry Sand

- As per ASTM G105 Wet sand

- As per ASTM B-611 Aluminium Oxide Slurry.

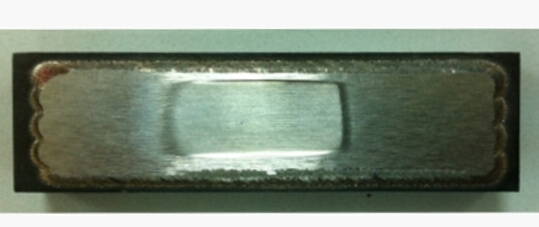

Moulds for Testing

Microstructure Testing (Bonding in cladding area)

Microstructure Testing (Hardening area)

HVOF Microstructures showing diamond indentation for hardness and bonding between base material and overlay. Porosities and Oxide formation testing also done.

Cladding Microstructures showing bonding, cladding thickness and HAZ.

Wear Testing:

- As per ASTM G65 Dry Sand

- As per ASTM G105 Wet sand

- As per ASTM B-611 Aluminium Oxide Slurry.

NON Destructive Testing Includes

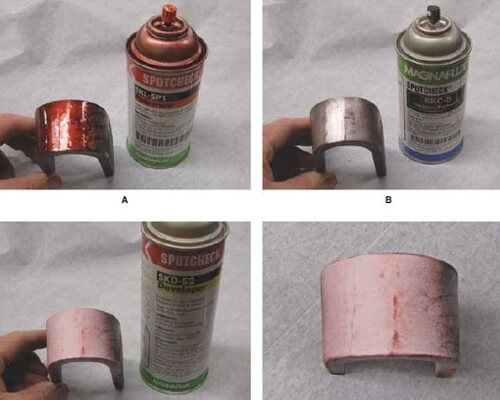

Liquid Penetrate Inspection

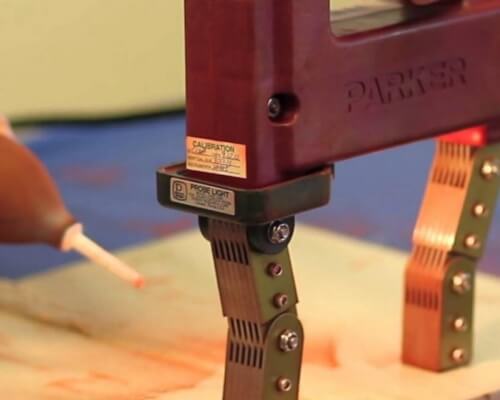

Magnetic Particle Inspection

Ultrasonic Testing

Magnetic Permeability Testing

We at PMMT have equipment for dimensional inspection of parts which cannot be measured by Micrometers or Verniers.

FARO-ARM

3D Scanner And Probing: